Screed is quite simply a thin, top layer of material laid over a concrete subfloor, that is traditionally made of sharp sand and cement, similarly to concrete. Industrial screed can be used for more heavy duty applications by using a more coarse 6-10mm aggregate.

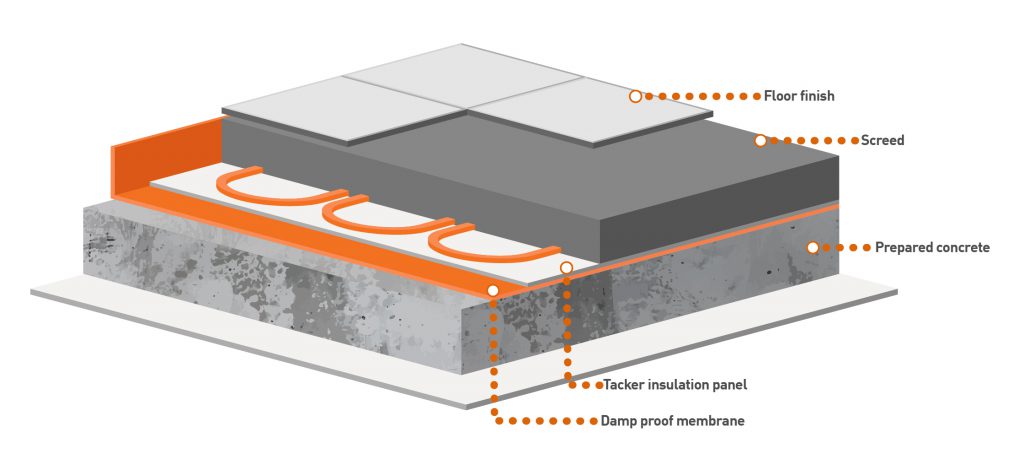

It is used to cover structural flooring concrete, and can be applied to either a solid, in-situ or precast concrete floor slab. It can also be laid on top of insulating materials, and is ideal for covering underfloor heating pipes.

It’s purpose is to provide a smooth, flat surface that other finishing materials, such as carpet, tile or floor boards, can then be laid on top of. Not only that, but it can also help to even out a floor surface, to ensure it is safe and level; as a rule of thumb the level of a floor should not vary more than 5mm over the space of 3 metres.

Screed and Concrete: What’s the difference?

Concrete and screed are both made of a cement, aggregate and water mix, the difference is that concrete is much coarser with more hard-core aggregates to provide increased strength, whereas screed uses finer aggregates for a smooth finish.

Screed generally costs more than the likes of concrete and mortar you can find out more about the cost of screed on our screed pricing page.

Types of Screed

There are three main types of concrete and the required one is dependent on the base: it can be bonded directly with the base, laid unbonded on top of a damp proof membrane, or applied as a floating layer of insulation material, such as underfloor heating.

The minimum thickness of each type of screed will vary depending on the application. Generally the more heavy duty the application, such as in industrial or heavy traffic areas, the thicker the screed will need to be.

However as a rule of thumb, for lightweight, domestic applications the minimum thickness should range from 25mm for a normal bonded screed, to 65mm for a floating screed or a screed over underfloor heating pipes. We always suggest you consult your structural engineer or builder who knows the specific requirements of your building site.

If required, screed can also be reinforced with a fine metal mesh, polypropylene fibres or a fine glass mesh.

Delivery Methods for Screed

Depending on the type of screed you require, it can be delivered in a few different ways. Here at EasyMix we send our vehicles out to mix your screed to the correct consistency and then deposit it on site ready for you to wheelbarrow to the required location.

Other companies can provide a specialist screed pumping service. A screed pump isn’t quite the same as a concrete pump as it delivers a dry mixture of screed that is essentially showered into the required location.

To find out more about screed, or to arrange a delivery from the experts at EasyMix simply get in touch today. We’ll be happy to discuss your requirements and ensure your screed arrives on site in plenty of time.