In recent years, the construction industry has seen incredible advancements in technology, revolutionising traditional building methods. One of these advancements is 3D concrete printing, an emerging construction technique that could well change the industry forever. This cutting-edge process involves using large-scale 3D printers to manufacture concrete in intricate patterns, creating entire buildings with unprecedented precision and efficiency. But is 3D concrete printing really the future of construction? That’s what the EasyMix team is here to find out!

The basics of 3D concrete

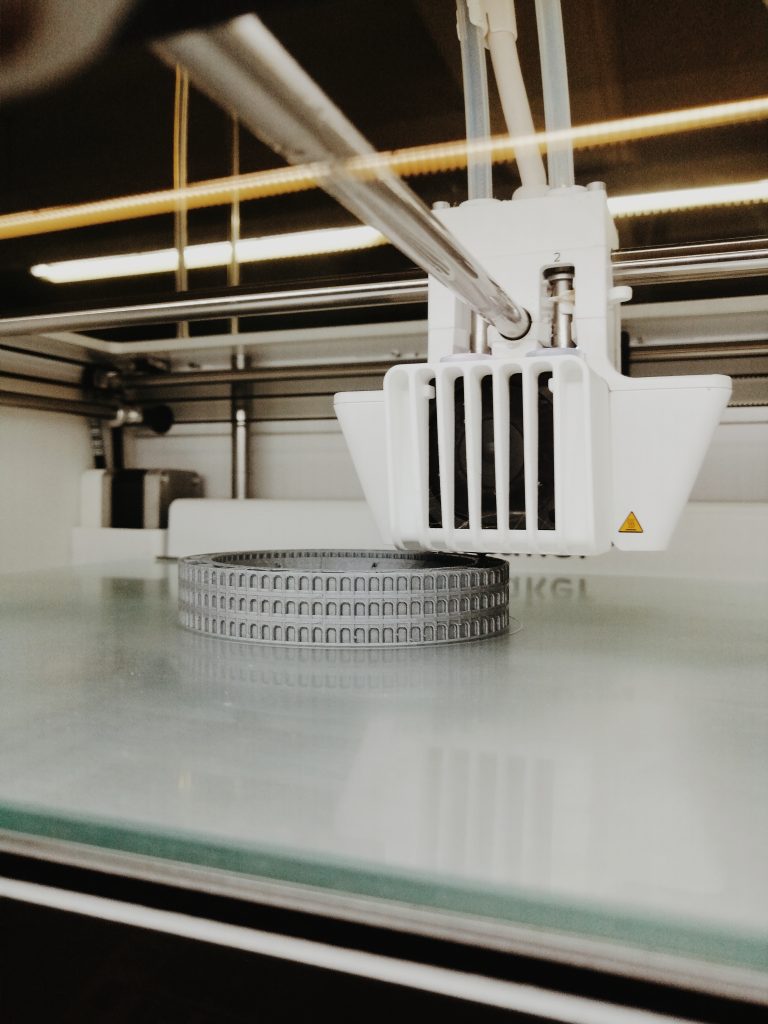

Before we discuss its potential, it’s essential to understand how 3D concrete printing works. The process starts with the development of a digital model or blueprint of the structure to be created. This model is then fed into a 3D printer, which interprets the data and precisely deposits layers of concrete in accordance with the design. Gradually, the layers stack on top of each other, ultimately forming the intended structure. Some advanced systems can even incorporate reinforcing materials like steel bars during the printing process.

The advantages of 3D concrete

3D concrete printing has a number of different advantages that make it an interesting prospect for the future of construction. First and foremost is the potential for cost cutting. By streamlining the construction process and reducing labour requirements, 3D printing can significantly lower overall building costs. Further, this technique minimises material wastage, as it only uses the necessary amount of concrete, making it more sustainable and environmentally friendly.

3D concrete printing also enables greater architectural freedom. Traditional construction methods often impose limitations on design complexity, but with 3D printing, intricate and innovative shapes can be created with ease. This opens up a world of possibilities for architects, pushing the boundaries of creativity and challenging conventional aesthetics.

Furthermore, the speed of construction is another compelling advantage. 3D concrete printing has the potential to build structures in a fraction of the time it takes using traditional techniques. This accelerated pace can prove vital in emergency scenarios, such as disaster relief efforts or addressing housing shortages.

Applications and real-world potential

While the technology is still in its infancy, several pioneers in the construction industry have already embraced 3D concrete printing and showcased its potential. Notable examples include the 3D-printed concrete bridge in the Netherlands, which demonstrated the viability of large-scale 3D printing for infrastructure projects.

As well as this, the construction industry has begun to explore the benefits of using 3D printing for low-income housing. The speed and cost-effectiveness of this technique make it a promising solution to tackle the global housing crisis, especially in developing regions where affordable housing is urgently needed.

Challenges and limitations

While 3D concrete printing shows great promise, it also faces several challenges that need to be addressed before it becomes commonplace in the construction industry. One significant concern is ensuring the structural integrity of printed buildings. Rigorous testing and adherence to quality standards are essential to guaranteeing the safety and durability of these structures over time.

Another hurdle is the availability of suitable materials. Specialised concrete mixes that are compatible with 3D printing are required for optimal performance. These materials must possess the right consistency and setting time to ensure smooth printing and robust end results.

It’s also worth noting that the initial investment in 3D printing technology can be substantial, which may deter some construction companies from adopting this technique until costs become a little more competitive.

EasyMix Concrete is one of London’s leading concrete companies, creating mixes that meet strict quality standards and also fit their intended application perfectly. If you’re interested in taking advantage of our concrete services, all you have to do is give us a call and we will be happy to help.